A new paper has been posted on the ResearchGate website by a Japanese team of scientists led by Osaka University professor emeritus Akito Takahashi, reporting successful production of excess heat from nano-metal and hydrogen/deuterium gas experimental systems.

The authors describe the effect simply as an ‘anomalous heat effect’ (AHE).

Title of the article: “Enhancement of Excess Thermal Power in Interaction of Nano-Metal and H(D)-Gas”

Authors: Akito Takahashi, Toyoshi Yokose, Yutaka Mori, Akira Taniike, Yuichi Furuyama, Hiroyuki Ido, Atsushi Hattori, Reiko Seto, Joji Hachisuka

Abstract: Significant enhancement of excess thermal power by the anomalous heat

effect (AHE) has been attained by our latest experiments on interaction of binary nano-

composite metal powders and H (or D) gas at elevated temperature of 300-400 °C.

Observed excess thermal power levels in average were 10, 86 and 186 W/kg-sample

for PNZ10, PNZ10r and PNZ10rr, respectively with deuterium-gas. In addition, levels

in average were 11, 117 and 226 W/kg-sample for CNZ7, CNZ7r and CNZ7rr,

respectively with light hydrogen gas. Generation of excess thermal power was very

reproducible by week cycle runs of heating power on/off mode, and was steady for

several days in each elevated temperature run.

EXPERIMENTAL METHODS AND PROCEDURE

The fabrication procedures ofPd-Ni/zirconia and Cu-Ni/zirconiafor nano-

composite sampleswere described in our previous papers [1-9, 11]. The outline is 1)

making thin (ca. 10 micron) amorphousmetalribbons of PdxNiyZrz or CuxNiyZrzmetal

composite alloys by the melt-spun method, 2) calcination in electric oven at ca. 450 °C

for 120-180 hours, and 3) making ca. 0.1mm size powdersby automatic mortaring

machine. The atomic ratios of x/y/z are from 1/10/20 to 1/7/14, approximately. In the

present work, we used Pd1/Ni10/Zr20 and Cu1/Ni7/Zr14 for PNZ10 and CNZ7 samples,

respectively. After the first H(or D) gas charging and elevating temperature runs (#M-

N, N=1,2,3), we took out the samplefrom RC (reaction chamber) to make re-

calcination in electric oven in ambient air with ca. 450 °C for ca. 180 hours. Then we

reused for the second H(D)-charging and temperature-elevation runs (#M-N, N=1,2,3).

Between M=1 and 2 or M=2 and 3, we made so called baking treatment with 250-

450 °C RC average temperature under vacuum-evacuation to meet the final RC

pressure of less than 1 Pa. The secondand third re-calcined samples are renamedwith

suffix r,as PNZ10r (orCNZ7r) and PNZ10rr (or CNZ7rr). The C system schematics

for AHE calorimetry at Kobe University has been many times shown [1, 2, 4 -9, 11].

Calorimetry calibration data are given in [8] for TC1-TC6, TC2-TC6, and RTDav-

TC6, by using blank sample of 1mm diameter zirconia beads (ca. 1.4 kg), for oil flow

rate 18.4 ccm. For heating up RC, we used constant power supply units by Keithley

Co., so that we did not need any correction for input heater power variation for [W1,

W2]= [120, 80] W and [140, 95] W ET (elevatedtemperature) runs.

H (or D) gas was initially filled in Gas Cylinder having volume of 4 litters (for H-gas)

and 2 litters (for D-gas), and fed to RC through Super Needle Valve. Initial pressure of

Gas Cylinder was 0.4 to 1.0 MPa. By adjusting the SNV path size, we set gas flow rate

as it took about 60 min to reach the equilibrium pressures at Ps and Pr[1-9], for the

case of blank calorimetry runs. Here Ps is pressure of source gas cylinder, and Pr is

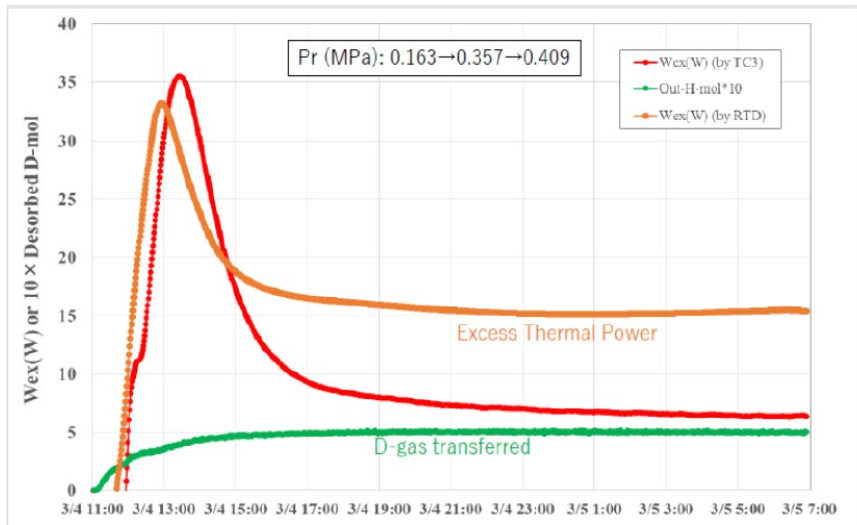

pressure of RC. When we had the AHE of significant amount, evolutiondataof Pr and

Ps were changed significantly from the blank runs. From the variation of Ps and Pr, we

could calculate rate of H (or D) gas molars (or number of atoms) transferred by the

runs. For present works, H-gas was used forCNZ7rr runs, and D-gas was used for

PNZ10rr runs.

Typical patterns of the AHE experiments areas follows;

0) baking the sample (#1-0, #2-0),

1) H (or D) gas charging to RC at room temperature (RT) (heaters: [0, 0], #1-1, #2-

1),

2) elevate RC temperature (heaters: [120, 80], #1-2, #2-2), run from Monday to

Friday

3) cool RC to RT (heaters: [0, 0], #1-3, #2-3), from Friday to Monday

4) elevate RC temperature (heaters: [140, 95], #1-4, #2-4), from Monday to Friday